As industries strive for sustainability, emission hotspots emerge as critical targets for reducing carbon footprints. These hotspots represent specific regions and sectors where significant upstream emissions occur. By addressing them, companies can drastically cut emissions linked to their products. This blog explores emission hotspots, their importance, and actionable strategies to tackle them effectively.

What Are Emission Hotspots?

Emission hotspots pinpoint areas where GHG emissions concentrate. They often lie in upstream production stages, far from the final product’s assembly line. For instance, manufacturing a car involves steel production, rubber processing, and electricity generation—each contributing to the total emissions. Identifying these hotspots reveals where interventions yield the greatest environmental benefits.

Transitioning to cleaner practices starts with understanding these high-impact zones. Companies gain insights into which countries and industries drive their carbon footprint. Consequently, they can prioritize efforts where change matters most. Emission hotspots, therefore, serve as a roadmap for sustainable transformation.

Why Emission Hotspots Matter

Global supply chains span continents, linking raw materials to finished goods. However, this complexity hides a stark reality: emissions often cluster in specific regions. Developed areas frequently consume products while the developing ones bear the environmental burden. Emission hotspots highlight this imbalance, urging action to level the playing field.

Moreover, targeting these areas aligns with climate goals. The Paris Agreement emphasizes rapid emission reductions to limit warming below 1.5°C. By focusing on emission hotspots, industries accelerate progress without waiting for new technologies. Existing low-carbon solutions can make an immediate difference.

Pinpointing Emission Hotspots in Action

Consider the automotive industry. Producing vehicles demands vast energy inputs, from mining metals to powering factories. Analysis shows that coal-based electricity in certain countries ranks as a top emission hotspot. For example, replacing fossil fuel power with renewables in these regions slashes upstream emissions significantly.

Similarly, the fashion sector reveals unique hotspots. Electricity-intensive processes like spinning and weaving dominate emissions. Retail and distribution also contribute, especially in countries reliant on non-renewable energy. Addressing these hotspots transforms the environmental footprint of clothing production.

Electronics manufacturing offers another case. Computer assembly relies heavily on energy-hungry processes. Coal-powered plants in key supplier nations emerge as emission hotspots. Shifting to cleaner energy here cuts emissions across the supply chain effectively.

Strategies to Tackle Emission Hotspots

Industries combat emission hotspots through targeted technology transfers. Low-carbon electricity stands out as a game-changer. Replacing coal with solar, wind, or hydro in hotspot regions delivers massive emission reductions. This shift not only cleans production but also lowers long-term energy costs.

Additionally, collaboration drives success. Companies partner with suppliers to deploy energy-efficient technologies. Training programs ensure these innovations take root. For instance, upgrading machinery in a hotspot steel plant boosts efficiency and cuts emissions simultaneously.

Trade adjustments offer another tactic. Importing from countries with cleaner production reduces reliance on emission hotspots. Alternatively, industries redirect sourcing to greener suppliers. While this approach shifts direct emissions, it encourages broader sustainability across global networks.

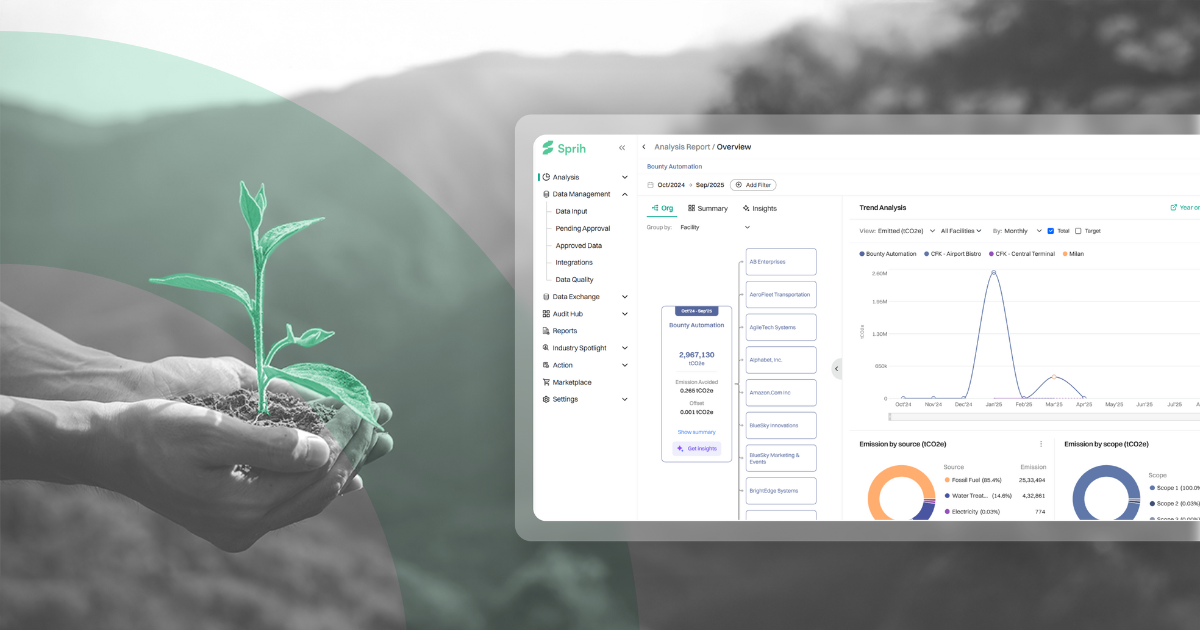

The Role of Data in Targeting Emission Hotspots

Data fuels the fight against emission hotspots. Advanced tools map emissions across supply chains, revealing hidden culprits. Multi-regional input-output analysis, for example, tracks CO2 from raw materials to final products. This method highlights hotspot industries and regions with precision.

Furthermore, benchmarks empower action. Companies compare their emissions against industry averages. This transparency sparks competition, pushing firms to innovate. Data-driven insights, therefore, turn awareness into tangible progress.

Benefits Beyond Emissions

Tackling emission hotspots delivers more than environmental gains. Cleaner production reduces energy costs over time. Suppliers using renewables or efficient tech become more competitive. Industries, in turn, strengthen their market position.

Additionally, sustainability boosts reputation. Consumers are increasingly favoring brands that address emission hotspots proactively. This demand drives innovation, creating a virtuous cycle of growth and responsibility.

A Call to Action for Industries

Industries hold the power to reshape emission hotspots. Start by mapping your supply chain’s carbon footprint. Identify key hotspots using reliable data tools. Then, invest in low-carbon solutions like renewable energy or efficiency upgrades.

Collaboration amplifies impact. Engage suppliers, industry partners, and peers to share knowledge and resources. Advocate for policies that support technology transfers to hotspot regions. Together, these steps shrink emissions effectively.

Looking Ahead: The Future of Emission Hotspots

The fight against emission hotspots evolves with technology. Innovations in energy storage and efficiency enhance solutions. Industries adopt these advancements, shrinking hotspots further. Meanwhile, data tools grow more precise, refining targeting efforts.

Governments play a pivotal role too. Stronger climate policies incentivize hotspot reductions. International cooperation accelerates technology diffusion. Together, these trends promise a cleaner, greener future.

Seizing the Opportunity

Emission hotspots offer a clear path to sustainability. They spotlight where action yields the biggest impact. By targeting these zones, industries cut emissions, save costs, and boost equity. The tools and knowledge exist—now is the time to act.

Visit www.sprih.com for more insights on sustainable practices. Let’s transform emission hotspots into opportunities for a better planet.

FAQs

What are emission hotspots in a production chain?

Emission hotspots are stages or processes within a supply or production chain that generate the highest levels of greenhouse gas emissions.

Why is it important to identify emission hotspots?

Identifying emission hotspots helps companies prioritize actions to reduce carbon emissions, improve efficiency, and align with sustainability goals.

How can companies detect emission hotspots?

Companies can use emissions tracking software, lifecycle assessments, and carbon accounting tools to pinpoint the most polluting stages in their production processes.

What role does supply chain transparency play in reducing emissions?

Supply chain transparency enables companies to trace environmental impacts across suppliers and make data-driven decisions to cut emissions at critical points.

How does addressing emission hotspots support ESG performance?

Targeting emission hotspots strengthens a company’s environmental footprint, enhances ESG scores, and supports compliance with climate disclosure regulations.